Twenty-four hours a day, seven days a week. From the boardroom to the front lines, Children’s Nebraska is mindful and mobilized, commissioned to be proactive, innovative and evolutionary. The nature of the opponent — equally relentless — requires nothing less.

“We work to create an environment in which potential problems are anticipated, detected early and responded to early enough to prevent harm,” says Amber R. Phipps, MBA, DBA, Children’s vice president of Quality & Patient Safety and a Major in the U.S. Army Reserves. “While rounding and talking with frontline staff, my favorite questions to ask are, ‘What’s the next harm event that’s going to take place?’ and ‘What keeps you up at night?’ – and we start looking at those themes that emerge.”

To ensure the highest levels of quality and patient safety, Children’s conducts gap analyses throughout the entire organization – from the hospital and Home Health to the specialty clinics and primary care offices. It also benchmarks itself with outside standards and embraces constant improvement. Later this year, Children’s will enhance its quality and safety program – and advance its organizational journey of high reliability – by formally implementing its Just Culture program.

The key themes in a Just Culture are continuous improvement and shared accountability: organizations are accountable for creating reliable systems and healthy environments, leaders are accountable for responding to errors in a fair and just manner, employees are accountable for the choices they make and all team members are accountable for reporting issues and vulnerabilities.

Keeping continuous improvement in mind, Children’s is also in the process of evolving from a Safety I mindset to an enhanced Safety II mindset, “looking at how we can avert error by redesigning the system,” says Phipps, whose proficiencies include process improvement, Six Sigma, lean principles and poka-yoke (a Japanese term for mistake-proofing).

Safety I (traditional thinking) was more reactive and viewed humans as a liability. Safety II behaviors are more proactive (how do you keep errors from taking place) and humans are partners in the process, a necessary resource.

“Safety II is no less than a paradigm shift in safety,” says Phipps.

Other recent innovations to Children’s multi-pronged patient safety and quality program include:

SACK A HAC

Utilizing artificial intelligence to minimize the risk of hospital acquired conditions (HACs)

Collaborating with internal talent and Epic, Children’s electronic medical record vendor, the hospital has created a system that identifies HAC bundle elements (a straightforward set of evidence-based safety practices) that are available in a patient’s chart. It outlines compliance criteria and ensures all these pieces are present and meeting Epic’s scoring logic.

Phipps gives an example, “Let’s say a child has a urinary catheter. They can potentially develop a urinary catheter infection. Literature shows that if you address all bundle elements, at least 90 percent of the time, the child will have a higher chance of not getting that HAC. If I forgot any one of the bundle elements, the system creates a red dot in the chart, indicating the patient has a probability of developing a catheter-associated urinary tract infection and these things need to be addressed.”

HACs in the Sack a HAC system, thus far, include unplanned extubation, ventilator associated events, falls, pressure injuries and catheter-associated urinary tract infections. Two additional HACs – central line blood stream infections and peripheral intravenous infiltration and extravasation – will be added later in 2019.

Complementary to the use of artificial intelligence is the Kamishibai card (K-card) process. K-cards allow for just in-time coaching, real-time solutions and spot-checking of bundle elements. Phipps says K-cards aim to increase bundle compliance by “keeping the bundle elements top of mind and reviewed at department-level safety huddles.”

DEPARTMENT SAFETY HUDDLES

Ensuring information flows from front-line staff to senior level executives and feedback flows back down, encouraging prompt communication, effective “loop closure” and greater safety awareness

“By implementing the safety huddles, we can confirm at our daily safety briefs (held 365 days a year) that our senior level executives have the right information to make operational decisions and ensure quick resolution for staff and patient safety issues,” Phipps says.

In addition, safety moments continue to be held at the beginning of every meeting that has a formalized agenda.

“You could be in the finance meeting for the Board of Directors and it starts with a safety moment,” says Phipps. “It’s just a constant reminder that safety is top of mind and our number one priority.”

THRIVE

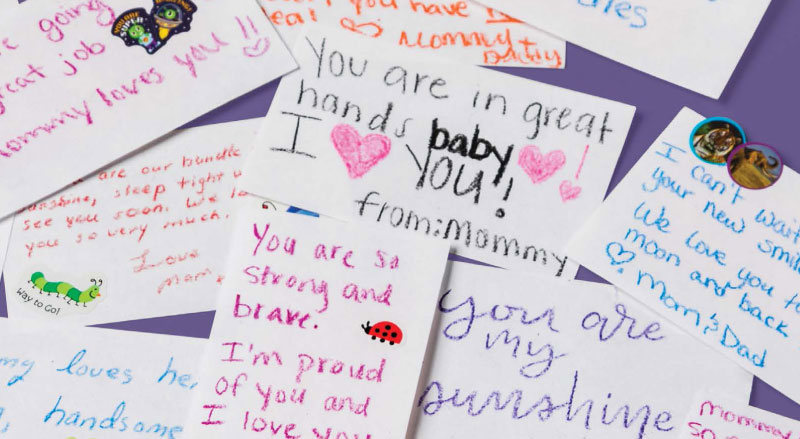

(Transforming Health care-related stress through Relational, Intentional and Versatile Empowerment) A three-tiered resiliency program offering support to empower staff and decrease burnout

The statistics are startling: an estimated 300 to 400 physicians die by suicide in the U.S. each year, and 35 percent of hospital nurses have reported a high degree of emotional exhaustion.

Children’s THRIVE program is both proactive, offering self care activities; knowledge of health care-related stress and team building; and reactive, providing three tiers of assistance to meet the needs of those seeking support.

“THRIVE is offering emotional support at all levels,” Phipps says. “We have trained 29 employees to provide real-time emotional first-aid and follow-up with employees encountering secondary traumatic stress. We will continue to build the program and train even more employees so our providers and staff continue to feel supported.”

All of the innovations – these initiatives and more – trace back to a belief that every child deserves to be surrounded by safety and contribute to Children’s ultimate goal of becoming a high-reliability organization (HRO). Preeminent HRO experts Karl Weick and Kathleen Sutcliffe define an HRO as an organization with systems in place that are exceptionally consistent in accomplishing its goals and avoiding potentially catastrophic errors.”

“To be a high-reliability organization, it requires a culture change, and it’s something that can’t be done overnight,” Phipps explains. “There isn’t a checklist of things to implement. It requires a complete way of thinking.”

And it can’t be done without total commitment. In effect, Major Phipps says ensuring the highest levels of safety and quality requires the creation of an army: “It can’t be one person. It can’t be one department. It has to be felt throughout the organization – just a relentless drumbeat.”

While Major Phipps is serving in the military, Alan Tingley, M.D., has stepped in as Children’s interim vice president of Quality & Patient Safety.